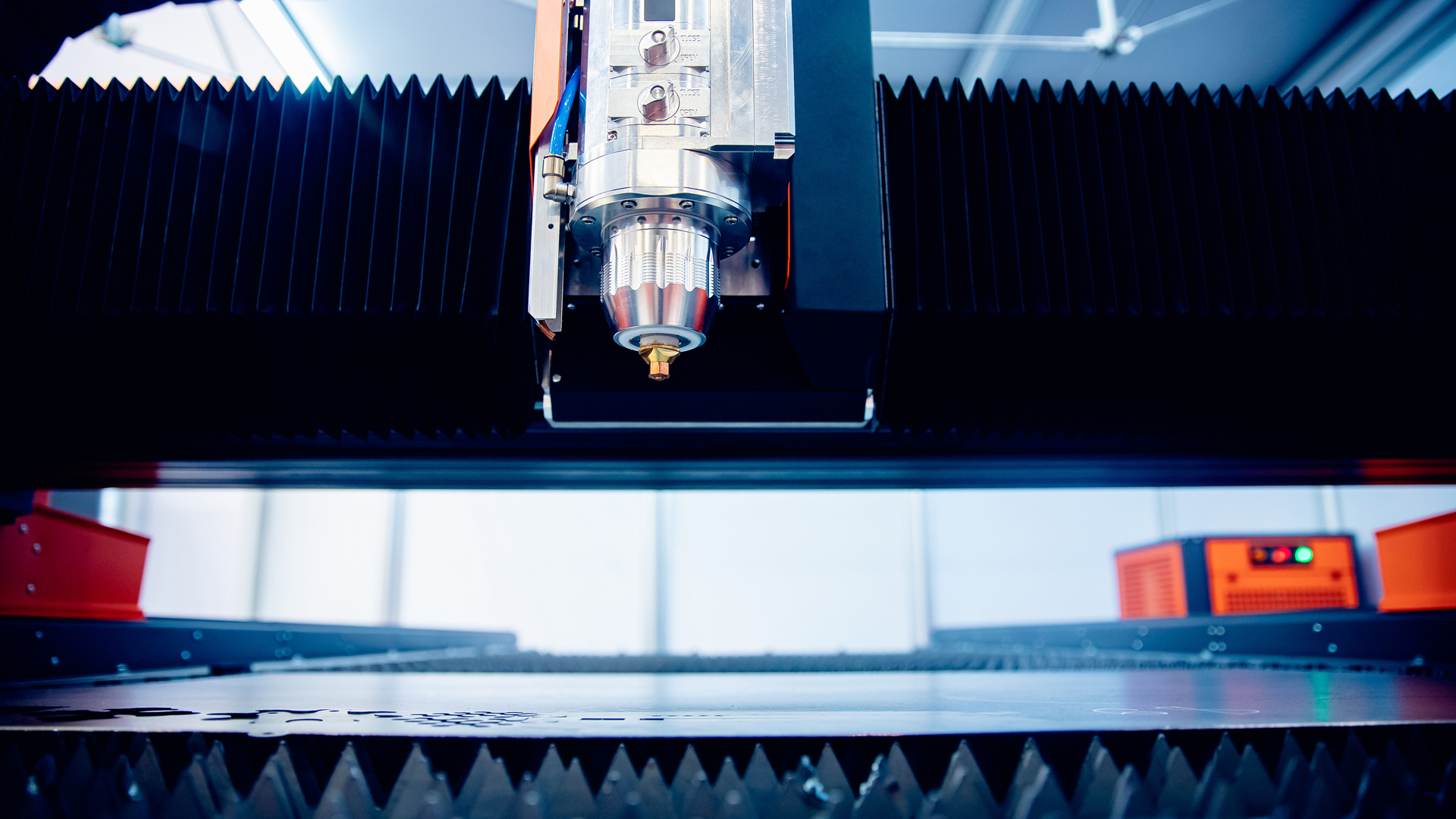

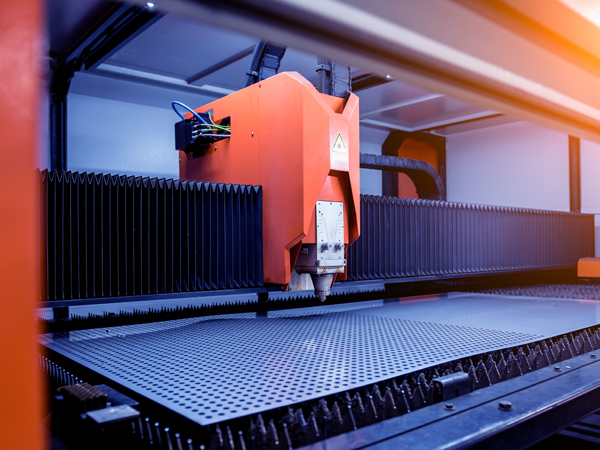

We process both thick (2.3 to 4.5) and thin (1.0 to 1.6) plates. We select materials such as steel plates, aluminum, and stainless steel depending on the application and usage environment.

We manufacture waterproof, dustproof, purge-enhanced, freestanding, desk, and wall-hung types, all in accordance with specifications. (Compliant with JIS, NEMA, IP CODE, NFPA/ISA, UL)

We apply baking coatings, powder coatings, and salt damage prevention coatings according to the environment. (We can also handle special coatings.)

We emphasize operability and maintenance, so perform layout and wiring which makes parts replacement easy.

Our company possesses highly reliable processing techniques for crimping, soldering, and wrapping connections, honed from years of experience.

We undertake internal wiring and piping using bare copper tubes, coated copper tubes, nylon tubes, and various types of SUS, among others.

We use fiber optic cables for reliable wiring.

We also perform various types of on-site construction work at the request of our clients.

We conduct inspections according to internal standards, including tests for appearance, power-on, pressure resistance, insulation, and operation. We also offer configuration of various instruments.

We perform comprehensive hardware and software inspections, primarily operational inspections.

We also develop educational plans and provide educational guidance according to your requirements.

We will provide completed documentation, manuals, etc., with emphasis on improvements and maintainability.